A comprehensive solution provider for smart factories

upgrading the manufacturing solutions

About us

SZ Viwistar Technology Co. Ltd.(Viwistar)

SZ VIWISTAR Technology Co.Ltd. (VIWISTAR) is a startup company focused on smart factory technologies, dedicated to providing one-stop services including technology, products, equipment, and comprehensive solutions necessary for intelligent upgrades in the fields of smart manufacturing and cold chain warehousing. Leveraging our core technologies in automation, machine vision, and mission planning, we endow machines, equipment, and production lines with recognition and adaptive capabilities, enabling companies to save significant labor costs by replacing workers in strenuous or hazardous work environments. This helps improve product quality, reduce production costs, and increase production efficiency. Our main products currently include intelligent powder coating workstations, smart solutions for assembly production lines, low-temperature automated storage cabinets, and WCS (Warehouse Control Systems).

The company has completed its Series A financing round. At present, our products have been implemented in multiple industries, including metal processing, home appliances, and automotive parts. The company is headquartered in Bao'an, Shenzhen.

TOP 50

Our team owns PHD and Master degrees from Top 50 Universities around the world

TOP 100

Core management and R&D personnel from world's Top 100 technology companies

10 Years +

Over 10 years of industry experience in AI25 +

More than 25 Intellectual propertiesSolving industry problems

Difficulty in upgrading manufacturing solutions

Recruitment and technical training problems

Recruiting technical personnel requires high requirements and training costs

Non-standardized work procedures

Manual inspection causes standard fluctuation

Harsh production environment

Harsh production environment causing harm to human body

Non-flexible operations

Traditional grippers can only grab specific objects

- Solutions

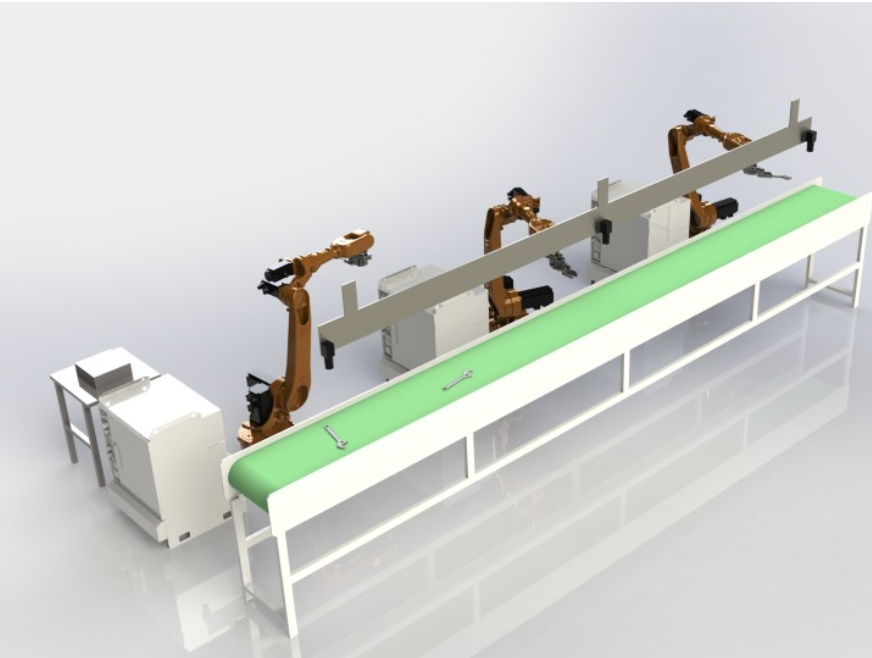

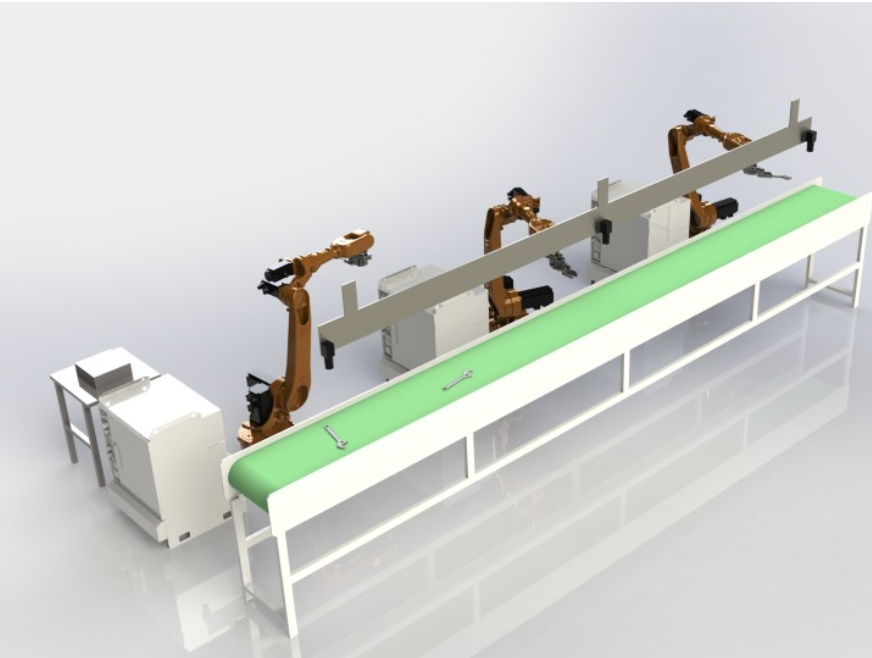

Randomize Picking Station

Vision-guided picking of metal tools

advantages:

‒ cost-effective

‒ up to 70% savings compared to non-intelligent systems

‒ hand-eye collaboration technology

‒ able to accommodate different objects

‒ minimal distruption to existing workflow set up

‒ optimized path planning

‒ comes with path planning algorithms and collision monitoringAssembly station

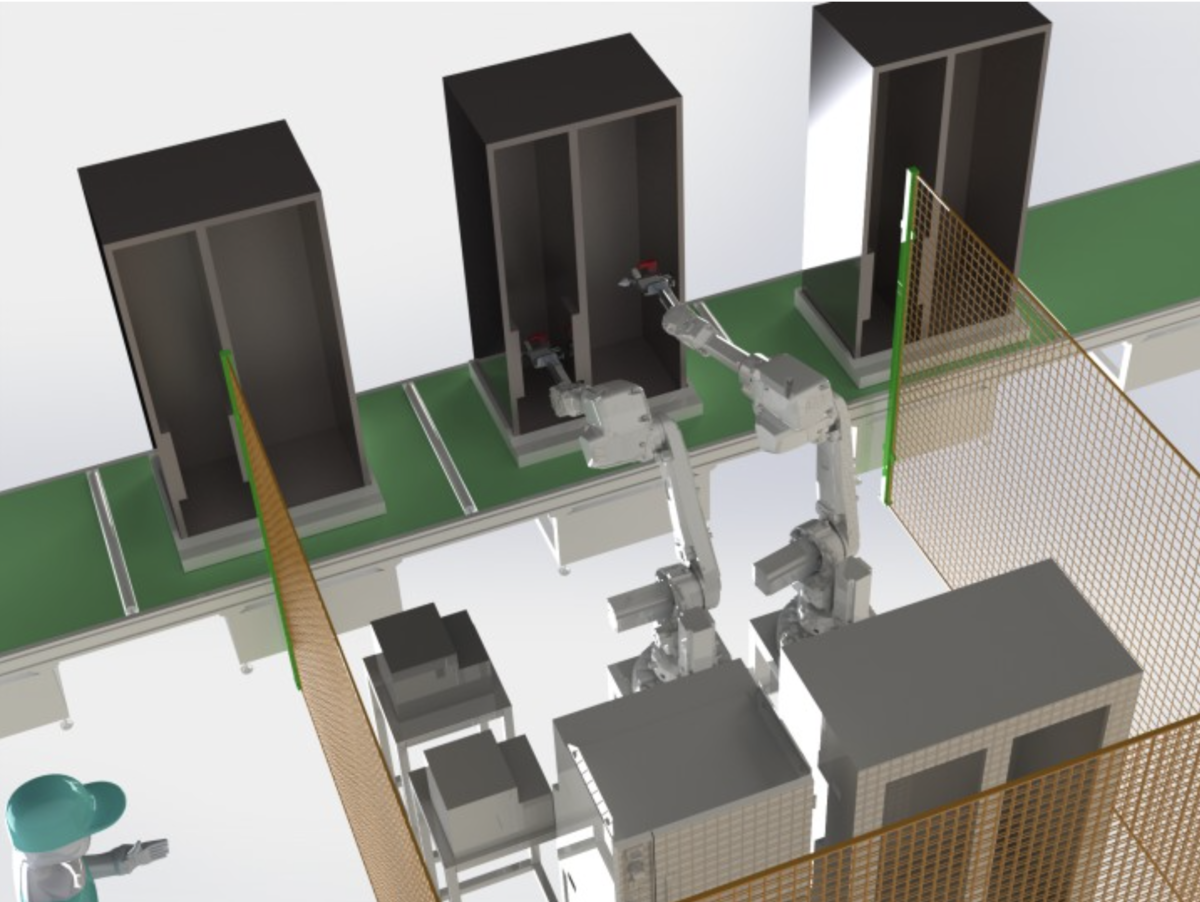

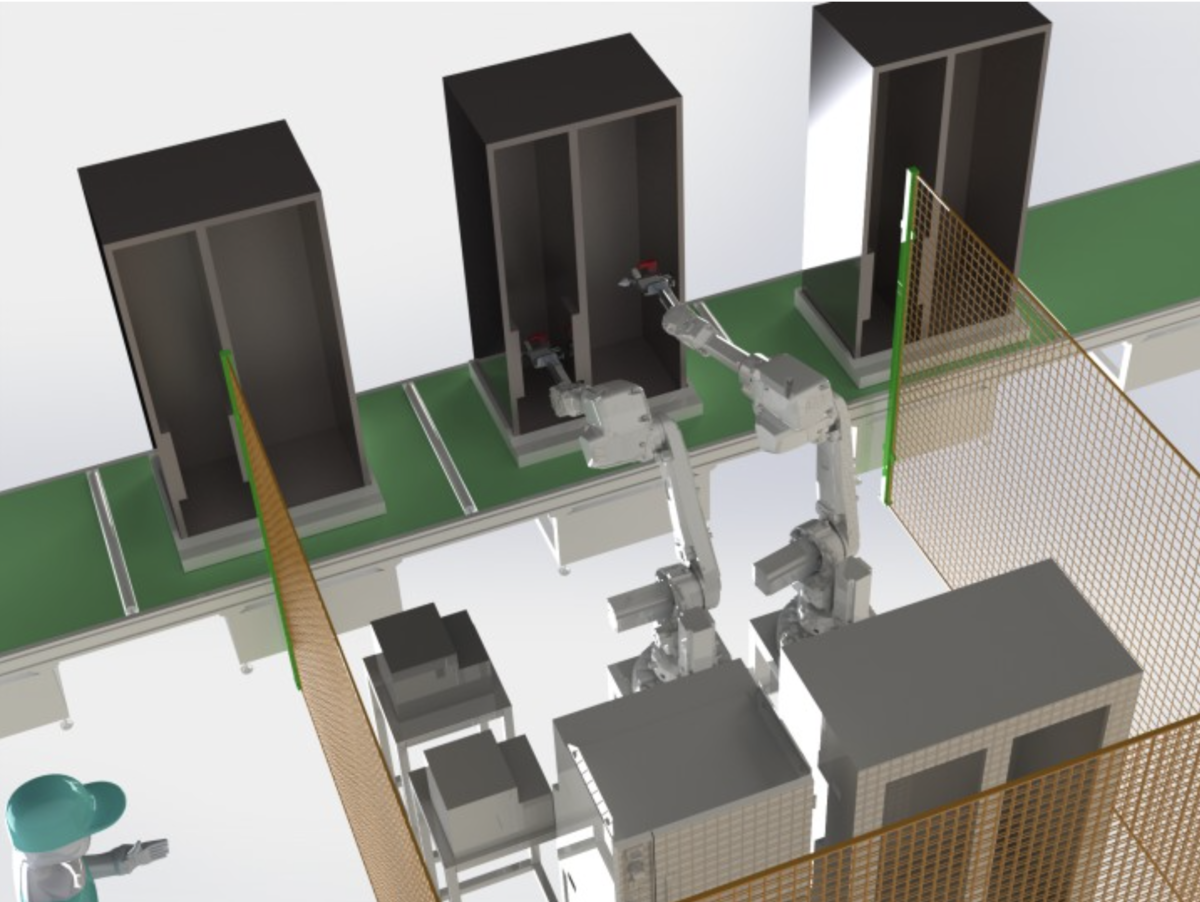

vision-guided assembly of refrigerator

advantages:

- cost-effective

- up to 70% savings compared to standard production systems

- hand-eye collaboration technology

- able to accommodate different objects

- minimal disruption to existing workflow set up

- optimized path planning

- comes with path planning algorithms and collision monitoring

Partners and Clients

Partnering with industry-leading companies to jointly create a new generation of intelligent, flexible and agile supply chain and manufacturing solutions